Design and Installation Considerations for solar Energy Storage Systems

Design and Installation Considerations for Photovoltaic Energy Storage Systems

|、 Pre-Design Considerations

1、Demand Analysis and System Capacity Design

* Load Matching and Redundancy: Precisely calculate user load characteristics (e.g., motor startup surge currents), with inverter capacity reserved by at least 30% to handle instantaneous power demands.

* Energy Storage Configuration: Design capacity at 1.5-2 times the average daily electricity consumption, adjusting photovoltaic array tilt angle based on the worst-case solar radiation (typically winter) by increasing 2°–8° over local latitude to enhance winter efficiency.

* Battery Selection: Prioritize lithium iron phosphate (LFP) batteries (cycle life ≥6,000 cycles) or lead-carbon batteries (low-cost scenarios); sodium-ion batteries are recommended for high-temperature regions (cost reduction: 30–40%

2、Environmental Adaptation Design

* High-Temperature and Dust Resistance: Use dust-proof and heat-dissipating designs for components and storage equipment. Battery compartments must have ≥100mm ventilation gaps and high-temperature alarms.

* Grid Compatibility: Adopt grid-forming inverters or virtual synchronous machine (VSM) technology to enhance frequency and voltage stability in weak African grids.

* Wind and Earthquake Resistance: Ensure brackets meet local maximum wind speeds (≥35m/s) and seismic standards. Use specialized clamps for corrugated roofs and chemical anchors for concrete foundations

3、Localization and Cost Optimization

Modular Layout: Use AC/DC integrated systems to shorten installation cycles and reserve 20% capacity for future expansion

||、Photovoltaic Panel Installation (Adapted for African High-Temperature and Dusty Environments)

1、Site Selection and Bracket Design

* Anti-Shading Optimization: Ensure ≤5% shadow coverage during 9 AM–3 PM on the winter solstice. Component spacing should be 1.5 times the height (e.g., 3m spacing for 2m-high brackets).

* Corrosion Resistance and Load-Bearing: Use galvanized steel or aluminum alloy brackets with chemical anchors in concrete foundations. Apply waterproof adhesive for corrugated roofs.

* Heat Dissipation: Maintain ≥100mm gaps between components and roofs/grounds. Double-glass panels reduce backside temperatures by 5–8°C.

2、Installation Specifications

* Mounting Methods: Prefer clamping blocks (bolt torque: 14–20N·m). Secure edge clamps first, then center components. Avoid impacts or stepping on panels.

* Electrical Connections: Connect "+" of the front panel to "−" of the rear panel in series. Use diagonal pliers to trim cable ties and confirm connectors with an audible "click".

Grounding: Use 12AWG copper wires to bridge adjacent grounding holes. Ground resistance ≤4Ω; multi-point connections for lightning protection.

3、Maintenance Adaptations

* Cleaning Frequency: Clean monthly in dusty areas (soft cloth + neutral detergent) to prevent 20% efficiency loss.

* Extreme Weather Protection: Check drainage holes pre-rainy season and inspect sealants post-sandstorms

|||、Energy Storage System Installation (LFP Battery Focus)

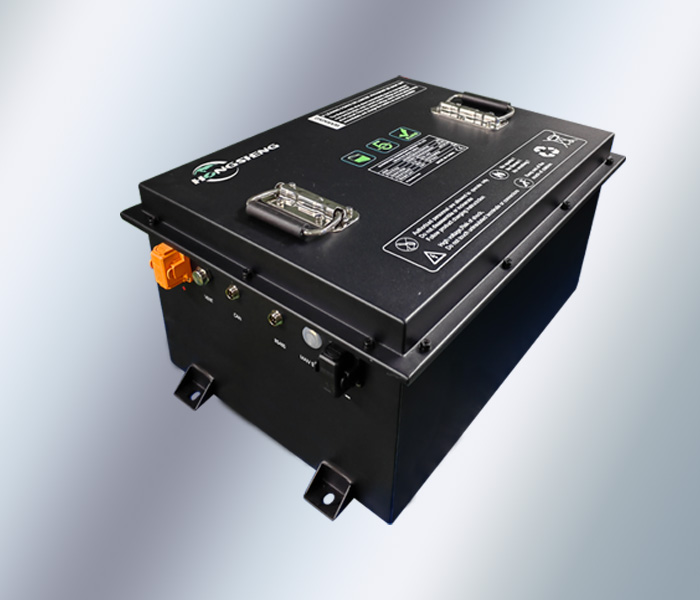

1、LFP Battery Selection and Configuration

* Capacity Calculation: Size based on 1.5–2 times daily consumption, optimized for low solar periods (e.g., African dry season).

* High-Temperature Adaptation: Use models with cycle life ≥6,000 cycles (operating temperature: 0–60°C). Equip battery compartments with liquid cooling or forced ventilation (airflow ≥0.5m/s).

2、Safety Requirements

* Independent Battery Room: Install away from crowds/open flames, with ≥300kg/m² load capacity, explosion-proof lighting, and fireproof materials (fire resistance ≥2 hours).

* Mounting and Heat Dissipation: Maintain ≥50mm spacing between battery groups, add insulation pads under trays, and monitor SOC/temperature via BMS.

* Lightning Protection and Grounding: Multi-point grounding for battery enclosures; shielding layers grounded at single points, complying with IEC 61643.

3、System Integration Optimization

* Modular Design: Allow 20% capacity expansion and integrate diesel generators for grid instability scenarios.

* Smart Dispatch: Use EMS to align with peak/off-peak tariffs (e.g., South Africa), prioritizing nighttime discharge for 40–50% cost savings.

4、LFP Battery-Specific Requirements

* BMS Functions: Monitor cell resistance deviation (≤5mV), temperature (sensor spacing ≤20cm), and programmable charge/discharge thresholds (e.g., SOC 20–90%). Implement short-circuit protection (response ≤50ms) and thermal runaway alerts.

* Cycle Life Management: Use shallow discharge (DoD 80%) to extend cycles to 8,000. Perform monthly balancing (voltage deviation ≤0.1V) and quarterly health checks

IV、 Inverter Requirements (Adapted for African Weak Grids)

1、Performance Parameters

* Wide Voltage Input: DC 150–1,000V tolerance for aging components and shading.

* Weak Grid Support: Grid-forming inverters (e.g., Huawei 150K series) with VSM, THD ≤3%, and 100% unbalanced load support.

2、Smart Features

* MPPT Optimization: Dynamic efficiency ≥99.8%, multi-peak tracking for shaded scenarios.

* Remote Monitoring: Integrate MBUS PLC communication to reduce wiring costs by 30%.

3、Protection Standards

Environmental Tolerance: IP65 dust/water resistance, operating range: −25°C–60°C, with PID recovery for high humidit

V、 Installation Phase Summary

1、Site and Safety Measures

* Indoor Installation: Near power rooms (≤100m), ventilated, load ≥300kg/m².

* Outdoor Installation: Elevate foundations against flooding, use anti-corrosion materials, and maintain ≥1.5m safety zones.

* Lightning Protection: Ground resistance ≤4Ω, integrated with building grounding systems.

2、Equipment Installation Standards

* PV Components: Ensure no shading, spacing at 1.5× height, and waterproof junction boxes.

* Battery Groups: Secure on dedicated trays, maintain ≥50mm spacing, and monitor via BMS.

* Cabling: Separate DC/AC cables, waterproof conduits, and insulated terminals.

3、Safety and Commissioning

* Professional Teams: Certified personnel, safety barriers for heights, and weather restrictions.

Testing: Simulate grid failures and battery over-discharge pre-operation, verify inverter anti-islanding response ≤0.02s.